Rongteng have been in natural gas industry since 1995. We provide solutions and equipment package for Wellhead treatment equipment, Natural gas conditioning equipment, Light hydrocarbon recovery unit, LNG liquefaction Plant, Gas generator sets. Our strong research and development make us to provide new products and solutions to satisfy the customers’ demands continuously. The technical team keeps eyes on the new technology and materials to meet the market’s requirements. With the advanced equipment, experienced staff, and strong production capacity, we can meet the customers’ production requirements and make quick shipment. One of Rongteng 's key advantages is its modular design and fabrication approach allowing for quick construction and superior quality control. Because of their modular design and construction, the entire plant can be easily shipped by sea. Our after sales service engineers will support the customers in installation and trial run, maintenance, personal training and spare parts replacement. .

We provide e Natural gas conditioning units to remove water, acid gas, nitrogen, mercury, heavy hydrocarbon from natural gas.

-

Complex iron method desulfurization proces and LO-CAT sulfur recovery

The complex iron desulfurization process is a wet oxidation method using complex iron as a catalyst to remove hydrogen sulfide. Its characteristic is to directly convert H2S in the gas into elemental S. After absorption, the H2S content in the gas is less than 20ppm. It is a new type of desulfurization technology with simple process, high working sulfur capacity, and environmentally friendly and non-toxic. The sulfur recovery rate reaches 99.9%, and the purified tail gas can meet the continuously improving environmental indicators. The complex iron desulfurization process is suitable for sulfur recovery units with H2S content of 0-100% and 0.1-20 t/d.

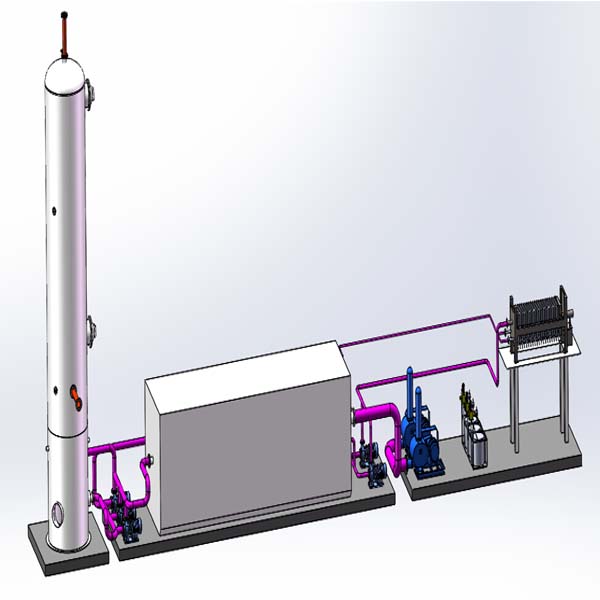

The optimal specification for a sled mounted complex iron sulfur recovery unit is a single set of sulfur less than 2 t/d.

Process application of complex iron method sulfur recovery

Process flow diagram of complex iron method sulfur recovery:

Advantages of complex iron method desulfurization technology

- Has high sulfur capacity

- Skid mounted

- Low desulfurization cost, energy-saving

- High operational stability

- Low investment

- High removal rate of COS and thiol organic sulfur

-

Natural Gas Purification System Molecular sieve desulphurization

With the development of our society, we advocate clean energy, so the demand for natural gas as a clean energy is also increasing. However, in the process of natural gas exploitation, many gas wells often contain hydrogen sulfide, which will cause corrosion of equipment and pipelines, pollute the environment and endanger human health. With the development of science and technology, The wide use of natural gas desulfurization technology has solved these problems, but at the same time, the cost of natural gas purification and treatment has increased accordingly.

-

7MMSCFD Natural gas decarbonization skid

● Mature and reliable process

● Low energy consumption

● Skid mounted equipment with small floor area

● Easy installation and transportation

● Modular design -

PSA decarbonization skid for natural gas purification

Natural gas decarburization (decarbonization) skid, is a key device in natural gas purifying or treatment.PSA is a low energy decarbonization technology that achieves CO2 adsorption and desorption by changing the operating pressure. This technology usually adsorbs and separates CO2 from natural gas at an operating pressure of 0.5~1MPa, and then undergoes vacuum desorption to complete the regeneration of the adsorbent. The PSA method belongs to physical adsorption, although compared to chemical adsorption, its adsorption capacity is limited and its selectivity is low; However, the PSA process flow is simple, the adsorbent has a long service life, is easy to regenerate, and has low energy consumption. At the same time, it also has advantages such as high automation, good environmental benefits, and high operational flexibility. Especially when dealing with high-pressure feed gas, there is usually no need to pressurize it again. The PSA method can be operated at room temperature without the need for heating and cooling, saving 1-2 times energy consumption compared to the TSA method; Moreover, compared to the equivalent TSA method, the PSA method requires much less adsorption dose.

-

Custom 50 ×104 TPD Natural gas dehydation treating plant

After water absorption, TEG is regenerated by the method of atmospheric pressure fire tube heating and regeneration. After heat exchange, the heat-depleted liquid is cooled and returned to the TEG absorption tower after pressurization for recycling.

-

Hydrogen sulfide fuel gas purification unit

Introduction With the development of our society, we advocate clean energy, so the demand for natural gas as a clean energy is also increasing. However, in the process of natural gas exploitation, many gas wells often contain hydrogen sulfide, which will cause corrosion of equipment and pipelines, pollute the environment and endanger human health. With the development of science and technology, The wide use of natural gas desulfurization technology has solved these problems, but at the same t... -

3 MMSCD Tailored Gas Dehydration Equipment For Natural Gas

We specialize in oil and gas field ground wellhead treatment, natural gas purification, crude oil treatment, light hydrocarbon recovery , LNG plant and natural gas generator.

-

Tailor-made Water Removal From Natural Gas By TEG Dehydration Unit

TEG Dehydration refers to that the dehydrated natural gas comes out from the top of the absorption tower and goes out of the unit after heat exchange and pressure regulation through the lean liquid dry gas heat exchanger.

-

MDEA method decarburization skid for natural gas conditioning equipment

Natural gas decarburization (decarbonization) skid, is a key device in natural gas purifying or treatment.

-

TEG dehydration skid for natural gas purifying

TEG dehydration skid is a key device in natural gas purifying or natural gas treatment. TEG dehydration skid of feed gas is wet natural gas purification, and the unit capacity is 2.5~50×104 . The elasticity of operation is 50-100% and the annual production time is 8000 hours.

-

Molecular sieve desulphurization skid

Molecular sieve desulphurization (desulfurization) skid, also called molecular sieve sweeting skid, is a key device in natural gas purifying or natural gas conditioning. Molecular sieve is an alkali metal aluminosilicate crystal with framework structure and uniform microporous structure.

-

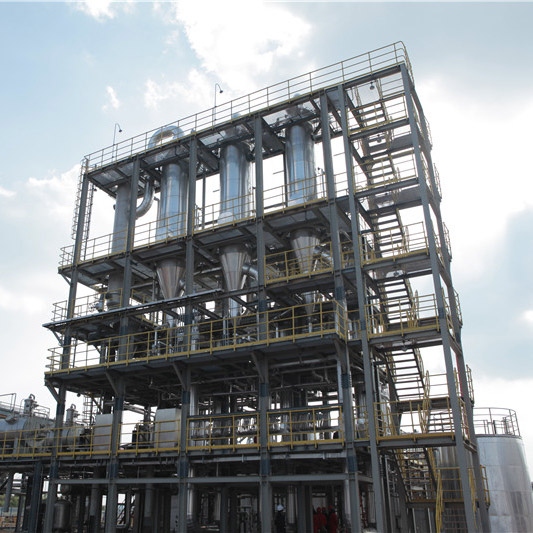

Evaporation crystallization skid

The application of evaporative crystallization skid in wastewater treatment of natural gas purification plant needs to be analyzed in combination with the phase diagram of Na2SO4-NaCl-H2O. Evaporative crystallization is not only the process of separating salt and water, but also can combine the solubility characteristics of each inorganic salt to separate the inorganic salt effectively by step in the evaporative crystallization system.