-

Complex iron method desulfurization proces and LO-CAT sulfur recovery

The complex iron desulfurization process is a wet oxidation method using complex iron as a catalyst to remove hydrogen sulfide. Its characteristic is to directly convert H2S in the gas into elemental S. After absorption, the H2S content in the gas is less than 20ppm. It is a new type of desulfurization technology with simple process, high working sulfur capacity, and environmentally friendly and non-toxic. The sulfur recovery rate reaches 99.9%, and the purified tail gas can meet the continuously improving environmental indicators. The complex iron desulfurization process is suitable for sulfur recovery units with H2S content of 0-100% and 0.1-20 t/d.

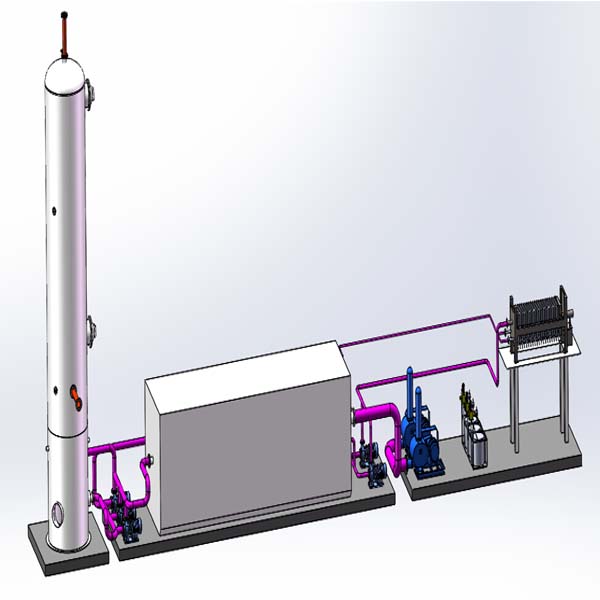

The optimal specification for a sled mounted complex iron sulfur recovery unit is a single set of sulfur less than 2 t/d.

Process application of complex iron method sulfur recovery

Process flow diagram of complex iron method sulfur recovery:

Advantages of complex iron method desulfurization technology

- Has high sulfur capacity

- Skid mounted

- Low desulfurization cost, energy-saving

- High operational stability

- Low investment

- High removal rate of COS and thiol organic sulfur

-

Natural Gas Purification System Molecular sieve desulphurization

With the development of our society, we advocate clean energy, so the demand for natural gas as a clean energy is also increasing. However, in the process of natural gas exploitation, many gas wells often contain hydrogen sulfide, which will cause corrosion of equipment and pipelines, pollute the environment and endanger human health. With the development of science and technology, The wide use of natural gas desulfurization technology has solved these problems, but at the same time, the cost of natural gas purification and treatment has increased accordingly.

-

Hydrogen sulfide fuel gas purification unit

Introduction With the development of our society, we advocate clean energy, so the demand for natural gas as a clean energy is also increasing. However, in the process of natural gas exploitation, many gas wells often contain hydrogen sulfide, which will cause corrosion of equipment and pipelines, pollute the environment and endanger human health. With the development of science and technology, The wide use of natural gas desulfurization technology has solved these problems, but at the same t... -

Molecular sieve desulphurization skid

Molecular sieve desulphurization (desulfurization) skid, also called molecular sieve sweeting skid, is a key device in natural gas purifying or natural gas conditioning. Molecular sieve is an alkali metal aluminosilicate crystal with framework structure and uniform microporous structure.

-

Natural Gas Sweetening Skid

MDEA natural gas desulphurization (desulfurization) skid, also called MDEA sweeting skid and natural gas desulfurization unit, is a key device in natural gas purifying or natural gas conditioning.

-

Natural gas sweetening equipment skid

Molecular sieve natural gas sweetening equipment (desulfurization) skid, also called molecular sieve sulfide removal from natural gas , is a key device in H2S removal from natural gas and natural gas treatment.

-

MDEA desulphurization skid for natural gas treatment

MDEA desulphurization (desulfurization) skid, also called MDEA sweeting skid, is a key device in natural gas purifying or natural gas conditioning.

Phone